Oilseeds Dehulling and Separation of Hulls

Proper treatment and preparation of seeds is a major prerequisite for the effectiveness of subsequent processing. It also influences the quality of final products: oil, press cakes, or extrudate. We are well aware of this, and that’s why, together with pressing and extrusion technologies, we have been constantly improving seed preparation technologies as well.

Quick and efficient livestock feeding requires the use of protein-rich feed, low in fibre. Hulling of the seeds is a smart solution for this issue.

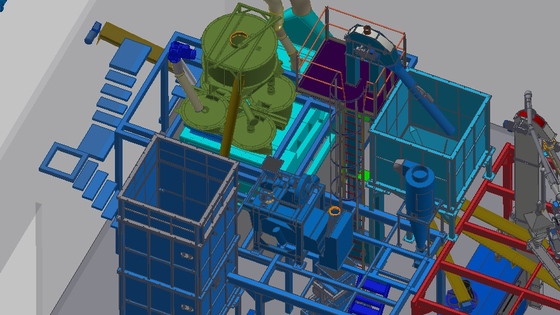

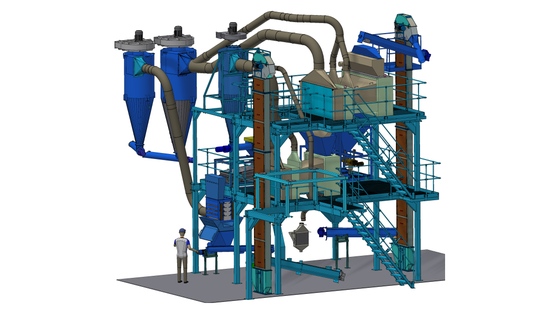

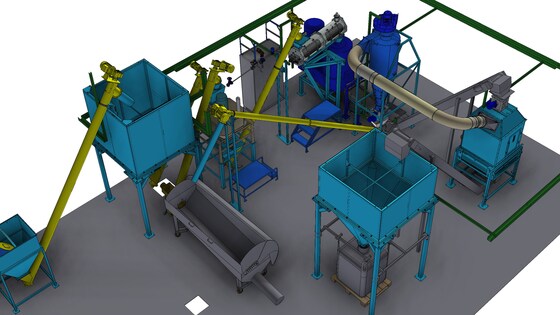

Hulling technology serves for partial removal of the hull from sunflower seeds and soybeans. Fibre content in the hulls is considerable, especially in the aforementioned types of oilseeds. Removing of at least a fraction of hulls in the processed material leads to a significant decrease of the overall fibre content in press cakes. Another advantage of hulling is higher oil yield during pressing. Hulling technology is offered at capacities ranging from 600 kg per hour (for the product “Compact”) to tens of tons per hour.

The technology also comes with complete engineering and other services, such as technical support, service possibilities, and accessible spare parts. For efficient operation, all technologies delivered by Farmet naturally come with a control system – Farmet Intelligent Control (FIC).