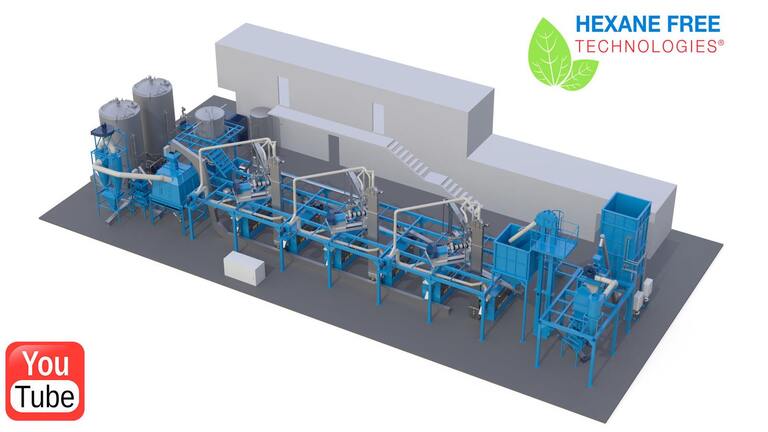

This technology EP2 provides maximal yield while using purely mechanical processing (no chemicals – hexane free) as well as the highest quality of pressing cakes, which are used as an excellent feed for livestock.

In the process of extrusion, thermal exposition to the processed material is very short, just as necessary for elimination of anti-nutrition agents, sterilization – destruction of germs of microbes and fungi – and for conversion of proteins and starches. Final expansion at the outlet of the extruder disrupts cell structures and enables better oil discharge in the second stage of pressing, resulting in high oil yield.

Oil obtained at the first stage of pressing is of the quality of cold pressed oil (high quality “virgin” oil with low content of phospholipids). We recommend to utilize separate processing of oils from the 1st and the 2nd stage of pressing (separate filtration and storage is necessary). The technology can be optionally equipped with a conversion set for single-stage extruder pressing, which enables to process oilseeds with oil content below 25% (such as soybeans) as well.

The technology is supplied with the system of intelligent control and visualization FIC (Farmet Intelligent Control).