The technology of one-level pressing with extrusion is convenient of oilseeds with oil content between 16-25 %. The best example is soybean. The technology produces a high-quality, filtered oil as well as press cakes, which can be used as an adequate substitute for extracted groats. Moreover, thanks to their higher oil content (7 %), these press cakes have a comparably higher energetic value. Thanks to the process of extrusion, anti-nutritional substances are reduced, which will be appreciated especially by the producers of feed for pigs and poultry.

Do you want to produce cattle feed? We have also optimized this technology for increasing the nutritional value of soybean press cakes by increasing the relative content of by-pass proteins (proteins that are only slowly digested in the rumen).

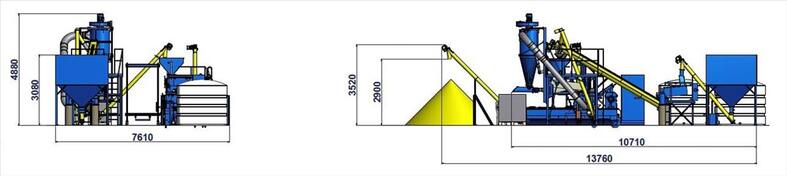

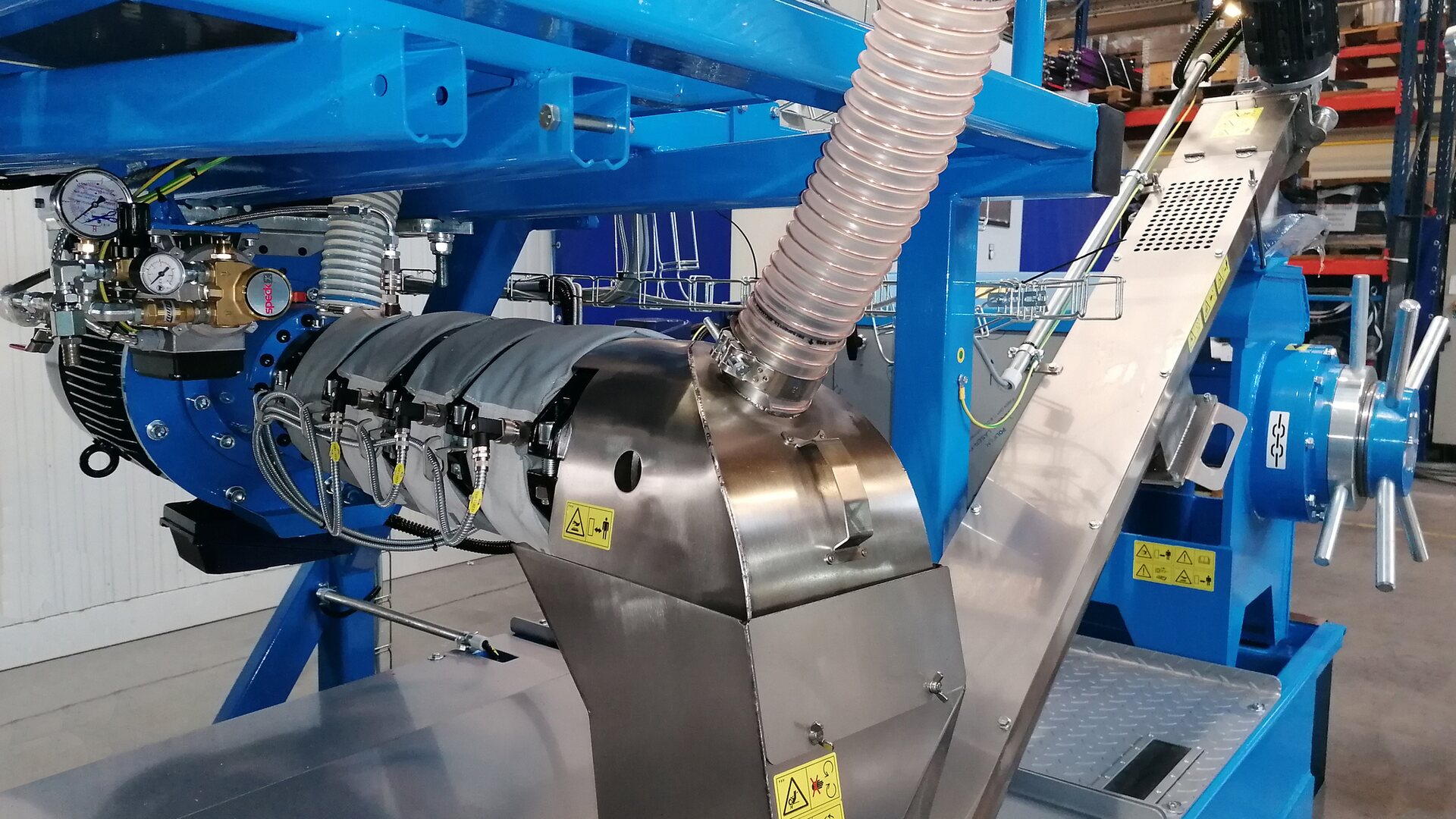

This is a technology of one-level pressing with extrusion. The material is fed into the hopper and then into the extruder FE 500, where extrusion occurs. The resulting extrudate is carried on an inclined conveyor into the press FS 350.

The expelled crude oil, still containing solid particles, flows into the settling tank, where sedimentation of the solids occurs. The sediment is then separated out by an integrated separator and returned back into the press for another round of pressing. The settling tank contains an integrated oil heating system, which, together with solids separation, guarantees a high efficiency of the filtration process.

The press shop Compact can be complemented with a range of accessories including seed pre-treatment, which consists of a magnetic separator, cleaning and a thermal stabilization of the seeds. Further accessories are a filtration unit that includes a pump integrated directly in the settling tank and a plate filter. The filtered oil is transported by a pipe into oil storage, which consists of two tanks with a volume of each either 1 m3 or 7 m3, depending on the customer’s requirements. Oil storage can be equipped with an outlet pump, which allows the oil to be transferred from the storage tanks into transport vessels or a cistern. A part of the pump is a work desk with a manual valve for bottling of oil into plastic bottles or cans.

Press cake storage contains conveyors, which transport the cakes out of the press shop.

The press shop Compact can further be equipped with the dehulling and hull separation module, which separates the kernels from their hulls and a part of the hull material is separated out as a by-product. This is convenient especially for sunflower seeds and soybeans. Press cakes from hulled seeds have a higher relative content of protein, which increases their feed value.

The extruder can also be equipped with a unit for dosing water into the extrusion chambers.

The modular press shop Compact EP1 is offered at performances between 250 and 500 kg per hour (performance for soybean processing).